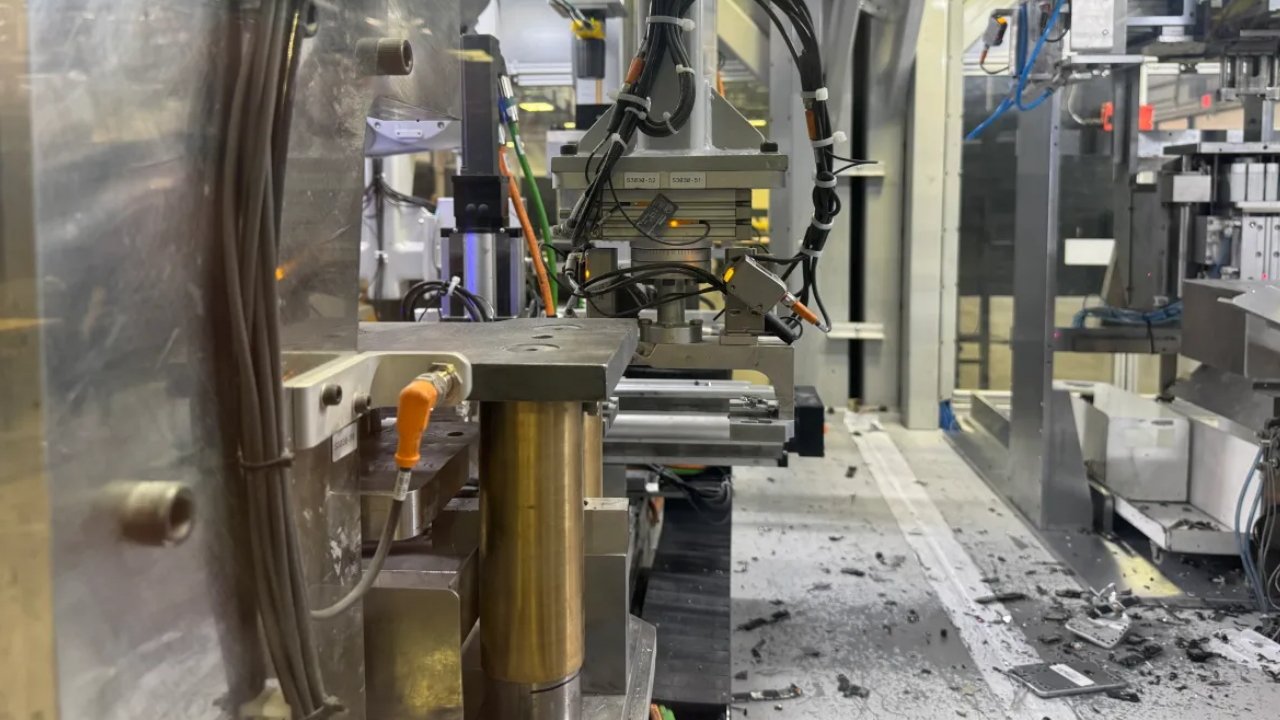

Discover the particles on the ground from Daisy smashing iPhones to get to their elements Daisy is comprised of 4 sections, all housed inside this one construction. (Photograph: TechCrunch, Brian Heater)

Apple has proven off its Daisy robotic for recycling iPhones earlier than, however now it is turn into a lot quicker through the use of brute power.

Daisy has been stripping previous iPhones for elements for a few years now, and is a part of Apple’s goal to finish mining for assets. it was itself an replace to a earlier robotic referred to as Liam, which might initially dissemble an iPhone in 12 minutes.

Later variations of Liam obtained that all the way down to 11 seconds, and in accordance with TechCrunch, Daisy now strips an iPhone in 4 seconds. Not less than as vital because the time-saving is that Liam might solely dissemble the iPhone 6, the place Daisy can deal with 29 completely different fashions.

“One metric ton of fabric recovered from Daisy prevents 2,000 metric tons of mining,” mentioned Sarah Chandler, Vice President of Surroundings and Provide Chain Innovation.

Regardless of the advantages, and regardless of its radically improved velocity, Daisy’s imposing 33-feet of robotics can strip as much as 1.2 million iPhones a yr — whereas an estimated 150 million smartphones have been discarded in 2023. Apple has provided to license its Daisy patents at no cost to anybody that desires it, however to date not one single firm has taken it up.

“I believe we have to proceed to do increasingly more with buyer engagement,” says Chandler. |That is why this is not going to be Daisy’s most efficient day… she’s operating somewhat slower to accommodate [a facility tour]. However that is value it. That is how we get the message out.”

Brute power recycling

Beforehand, Apple’s recycling robots used to grip the iPhone and fairly painstakingly unscrewing and eradicating every element. Now these elements are punched straight out of the machine, ripping aside the iPhone for velocity.

The method is finished in a sequence of 4 phases, beginning with bucketfuls of iPhones being dropped right into a chute. Daisy places each on a conveyor belt, and makes use of machine studying to find out what particular mannequin it’s.

Subsequent the show is peeled off, and every machine is subjected to temperatures of -80 levels Celsius (-112F), which makes adhesive within the batteries fail. Daisy then knocks that battery out, and the iPhone continues to the subsequent phases.

These finish with elements touchdown on a spinning floor, the place a human being will kind them. Then boxed-up units of elements are despatched out to e-waste corporations.

Daisy is comprised of 4 sections, all housed inside this one construction. (Photograph: TechCrunch, Brian Heater)

Recycling in Austin, Texas

Whereas these e-waste companies are exterior, Apple says that it goals to do as a lot of the recycling in-house as it could possibly.

“It is so necessary to do it internally,” says Patrick Wieler, Recycling Innovation Engineer. “Each evolution taught what we will do with automation and offers us an enormous step ahead.”

“It is a fixed dialogue,” he continues. “We study a ton from the automation crew engaged on the brand new merchandise, as a result of they’re at all times confronted with their very own distinctive set of challenges.”

“We will construct on their studying there after which vice versa with their groups,” he says. “After we share how we have been programming Daisy, it permits them to consider new approaches to the automation of latest merchandise.”

Apple has two of the Daisy recycling robots, with one primarily based within the Netherlands, and one in Austin. Chandler says being primarily based in Austin has been significantly helpful to her crew.

“We have got sturdy, longstanding connections right here,” she says. “We have clearly obtained a number of massive campuses right here, so we’re in a position to do a bunch of recycling right here.”

“And it has been nice for educational partnerships, too,” continues Chandler. “We’re in a position to get fairly a couple of interns… we get rather a lot of us who need to discover robotics, recycling and materials restoration.”

Individually, Apple has been increasing its Austin campus, even a it shuts down others together with a San Diego workplace. Some 121 folks from that workplace have been provided roles in Austin.