Information briefs for the week check out the brand new pattern in manufacturing referred to as microfactories—the place robots rule, a first-ever, ready-to-use 3D printing cupboard, T-skin security sheathing for cobots and industrial robots, and a do-it-yourself 3D printed cobot for desktop manufacturing.

Microfactories: The place robots rule!

Are microfactories the way forward for manufacturing? There’s a manufacturing facility automation pattern that’s simply starting to take maintain that deviates radically from the usual meeting line, particularly these in auto crops. Korea’s Hyundai has constructed such a completely completely different auto plant for its electrical automobile manufacturing (EV) in Singapore.

The Hyundai plant is made up of pods or cells the place 60% of the manufacturing of the Ioniq 5 EV is completed by robots (see video); the remaining 40% is accomplished by human staff alone or in partnership with robots.

The Hyundai plant is made up of pods or cells the place 60% of the manufacturing of the Ioniq 5 EV is completed by robots (see video); the remaining 40% is accomplished by human staff alone or in partnership with robots.

The web-net in relation to workers is that it makes use of solely 100 staff to provide 30,000 automobiles a 12 months. In pod assemblies, robots rule!

Alpesh Patel, VP of Innovation at Hyundai, thinks {that a} microfactory’s cell manufacturing technique might effectively be customary in just a few years. General price discount to fabricate is 50% lower than a standard or totally customized automated line. “It’s because modules use 70% of the identical parts (body, energy, security, conveyor system).” Plus, improvement and meeting time is often 50% lower than a completely automated customized line.

“Within the cells” writes Suvrat Kothari, “robots set up parts of a automobile, earlier than transferring to the following zone. The important thing differentiator is that the cells will be programmed with particular directions, proper from putting in parts for various variants of the identical automobile, or to engaged on a totally completely different mannequin. Conventional meeting traces would want important retooling for comparable adaptability.”

The cells are linked collectively by a standard conveyor and feeder system, able to offering excessive quantity, excessive combine manufacturing functionality.

Modular automation can scale up or down simply. “Relying on the complexity of the product or sub-assembly, producers can simply anticipate to get 3-4k models’ per hour (UPH), or 1 million models a month.”

Prepared-to-use 3D printing robotic

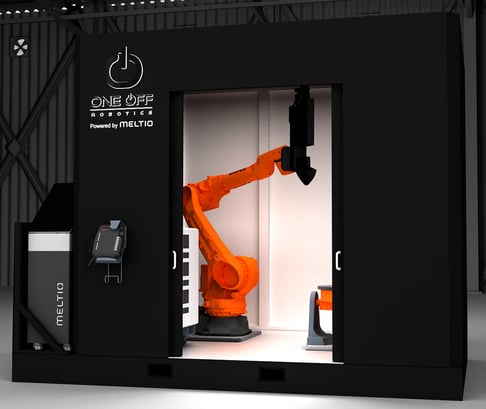

Market want: Prepared-to-use, turn-key system offering an environment friendly, quick, and secure answer for manufacturing metallic 3D printed components,  particularly with stainless-steel, nickel, and titanium. To fulfill the necessity, Spain’s Meltio and US-based One Off Robotics partnered for the manufacturing of a self-enclosed 3D printing cupboard.

particularly with stainless-steel, nickel, and titanium. To fulfill the necessity, Spain’s Meltio and US-based One Off Robotics partnered for the manufacturing of a self-enclosed 3D printing cupboard.

Meltio is a producer and developer of wire-laser metallic 3D printing applied sciences, and One Off Robotics is a builder of robotic arm fabrication programs for additive, subtractive, and hybrid manufacturing processes.

In combining their applied sciences, they declare a first-ever, turn-key answer to supply industries with an environment friendly additive manufacturing work cell named the One Off Robotics Cell. In keeping with Meltio Product Supervisor, Alejandro Nieto, “This new {hardware} system permits the client to obtain a ready-to-use cell for robotic metallic 3D printing, eradicating the combination course of and lengthy meeting lead instances.”

With a deposition fee of as much as 1 kg an hour, this technique produces totally dense components which are mechanically equal or superior to these created from conventional means.

The One Off Robotics Cell seamlessly integrates management of the system, permitting the person to simply regulate settings for fast printing. Its 8-axis system simplifies printing of complicated geometries and is configured to work with the Meltio Area robotic slicer.

Security pores and skin stops robots immediately

Retaining staff secure from cobots has all the time been a priority; extra so with cobots than customary industrial robots, that are normally segregated from staff by fencing or partitions.

In 2016, FANUC launched contact-sensing cobot security padding which had been polyurethane foam pads utilized to the outside of cobot arms. Stopping time in 2016 was 9 milliseconds.

Practically ten years on, Taiwan-based Touche Options (previously named Mechavision) has lately developed a contact-sensing movie of security materials that’s additionally utilized to the outside of not solely cobot arms but in addition to these of commercial robotic arms. Referred to as T-skin, it has a stopping time of 1 millisecond. Wish to know the way lengthy a millisecond is? Try the video under.

Practically ten years on, Taiwan-based Touche Options (previously named Mechavision) has lately developed a contact-sensing movie of security materials that’s additionally utilized to the outside of not solely cobot arms but in addition to these of commercial robotic arms. Referred to as T-skin, it has a stopping time of 1 millisecond. Wish to know the way lengthy a millisecond is? Try the video under.

Touche Options’ founder and chairman, Camus Su, and common supervisor, Liu Changhe, are graduates of the Industrial Know-how Analysis Institute (ITRI). Their collaboration in 2017 led to Touche Options, which emphasizes “tactile sensing expertise to set off emergency stops in robots, serving as a vital security measure past visible and light-weight grids.”

The founders declare that T-Pores and skin, was developed based mostly on the ISO customary unit of 10 newtons (1kgf) that triggers emergency stops in response to an exterior pressure of 1 kilogram, inside 1 millisecond, and is unaffected by both electromagnetic waves or RF.

A main goal of Touche Options is “to outfit conventional industrial robots with collaborative [cobot] capabilities, which has garnered fast recognition from main Japanese robotics corporations (FANUC, Kawasaki, and so on.).

All of which means that industrial robots can now, with the addition of T-skin, tackle jobs previously meant just for cobots working in and round individuals.

DIY 3D printed desktop cobot

Acquired a small-shop enterprise with a lot of desktop manufacturing wants? Want a stable instructional cobot arm for studying tasks? Wish to market and promote cobots on-line to a worldwide viewers? Introducing the award-winning PAROL6 (Supply Robotics).

Roboticist Petar Crnjak is hoping to convey industrial-style robotic arms to a wider viewers with an open-source 3D-printable six-axis design dubbed the PAROL6 — providing help for a powerful 2.2lbs (1kg) payload.

Roboticist Petar Crnjak is hoping to convey industrial-style robotic arms to a wider viewers with an open-source 3D-printable six-axis design dubbed the PAROL6 — providing help for a powerful 2.2lbs (1kg) payload.

Crnjak says his “PAROL6 is a high-performance, 3D-printed desktop robotic arm, with a design strategy just like ” of his creation. “The design strategy of PAROL6 was to be comparable “to industrial robots when it comes to mechanical design, management software program, and usefulness. Management software program, GUI [Graphical User Interface], and PAROL6’s STL recordsdata are open supply.” Except for a pneumatic gripper, every axis is pushed by a stepper motor, with at the least just a few of those axes being pushed by means of a metallic planetary gearbox for further precision and torque.

Relying on ones’ degree of experience, PAROL 6, with entry to a 3D printer and on-line design specs (free), it may be a DIY mission; it additionally is available in package kind; or bought able to go straight out of the field for $3.200 (3,000 euros).

“By pairing industrial mechanical design with state-of-the-art software program and electronics, the PAROL6 robotic can obtain clean motions, excessive speeds, and excessive repeatability. PAROL6 is constructed with schooling, analysis, and small automation in thoughts!”

![]()